What Is DSF (Diamond Scratch Finder)?

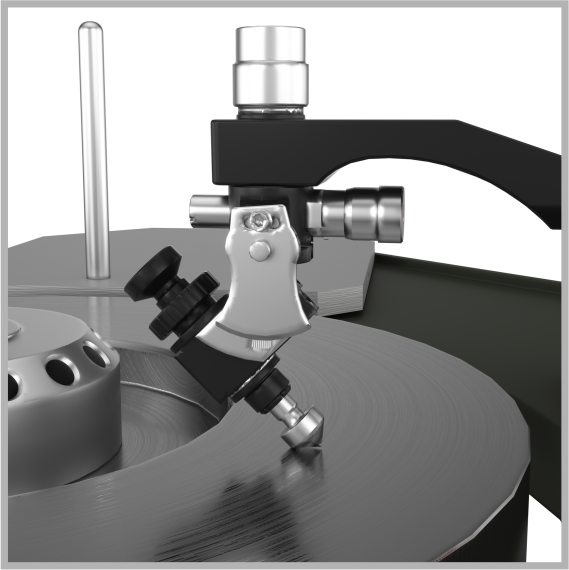

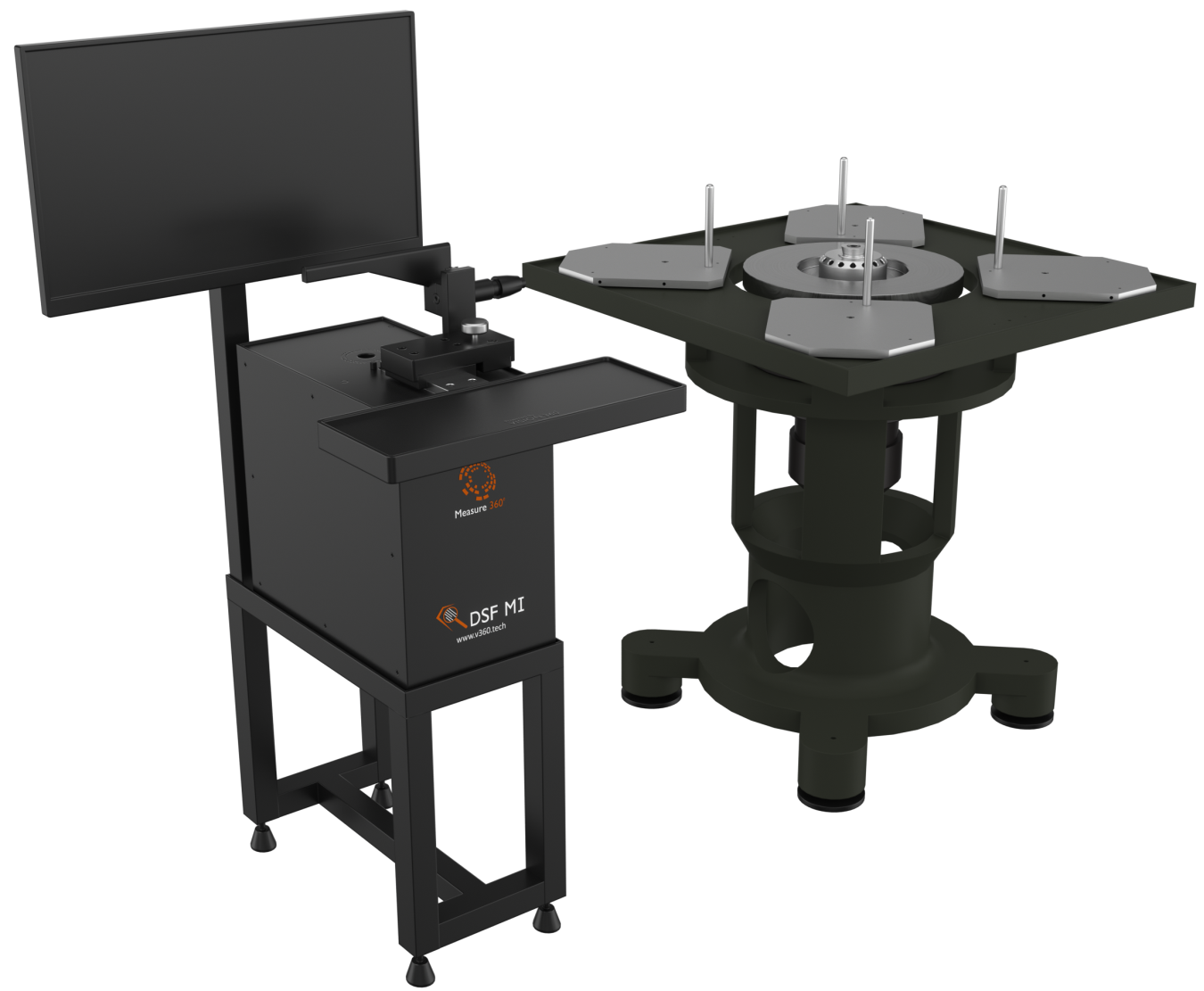

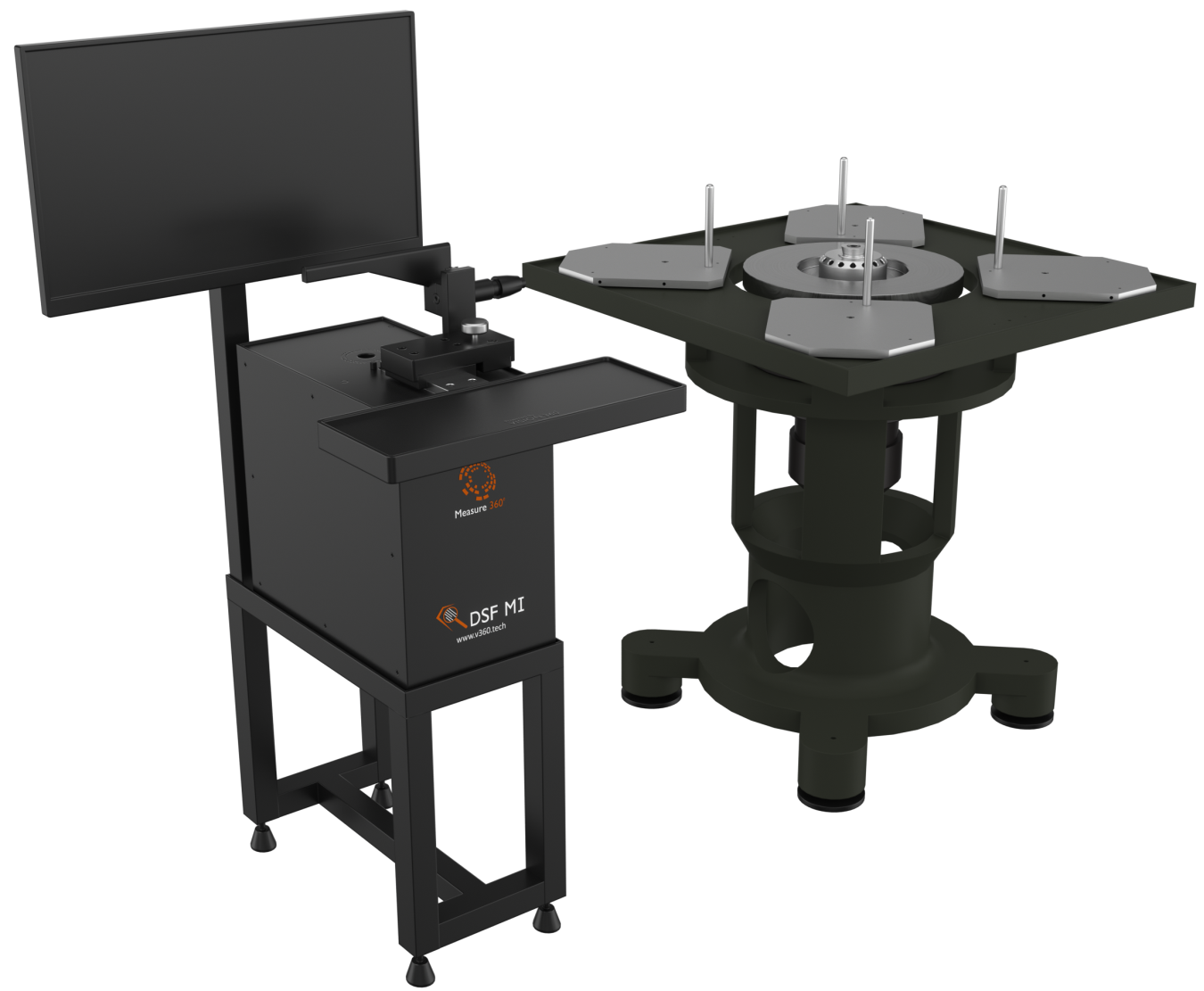

DSF is a machine-vision based tool to visualize the surface quality of diamond during polishing. It replaces manual inspection of the diamond field in tang using a loupe with a camera-based vision on a large display. Also, Image processing algorithms give polish grad in live view as well with a detailed and enhanced view of the diamond surface.

Advantages

- No need to use a loupe to inspect the surface quality of the diamond during polishing. Diamond is visible on a large screen which gives a detailed overview of the surface being polished. It saves a lot of me considering Polisher has to watch through loupe multiple times during the entire process.

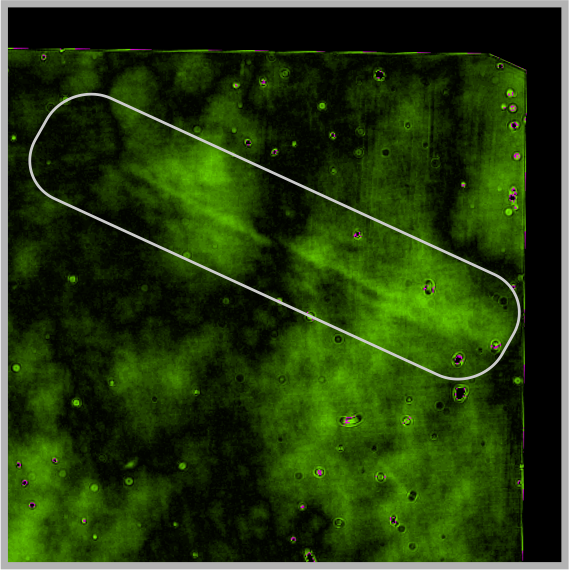

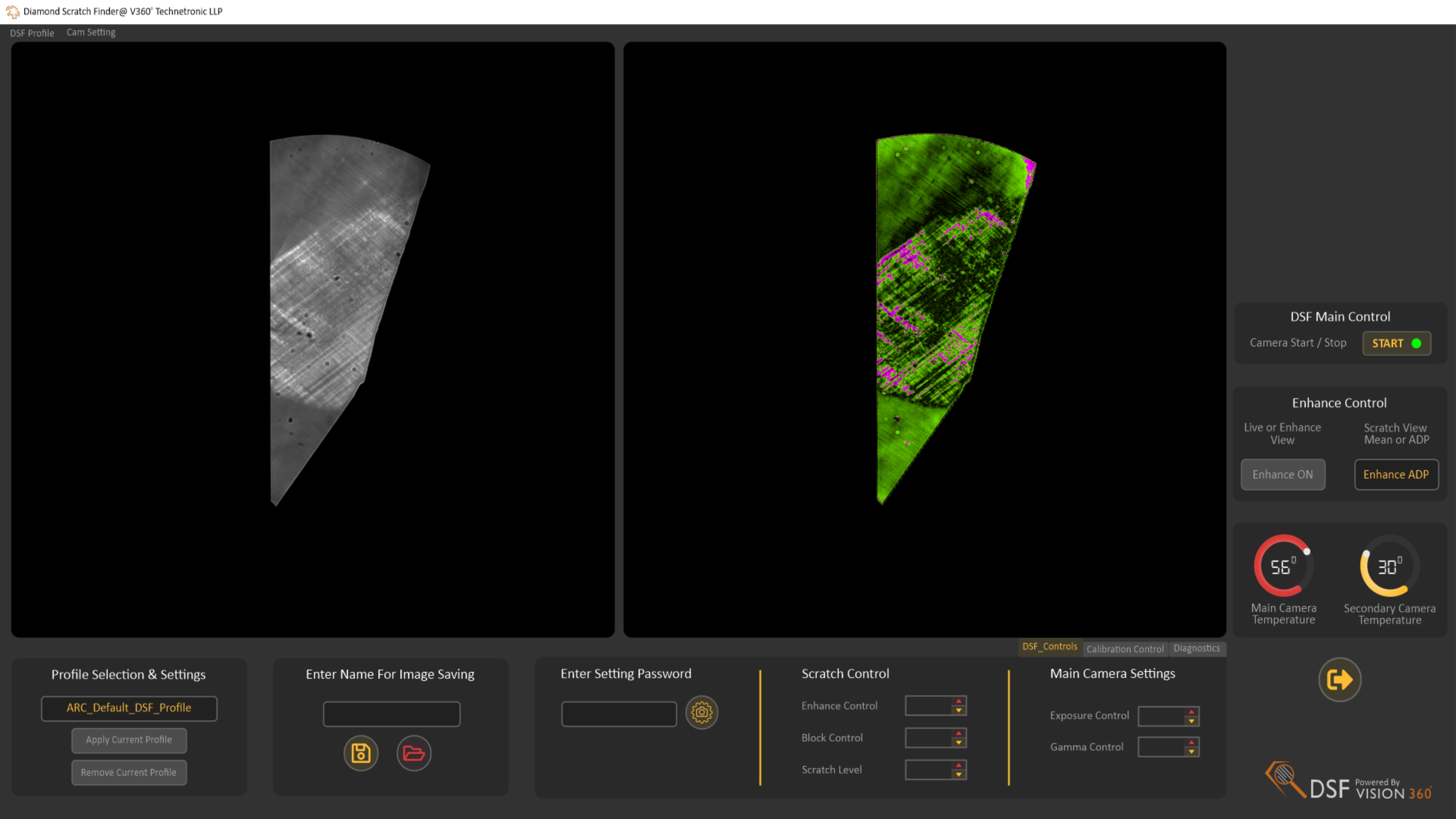

- DSF has “Enhanced View” which provides artificially improved images of the surface. Even inexperienced Polishers can easily understand the scratch levels without missing any details.It is very easy to achieve “Ideal” polishing repeatedly.

- Due to the precise and calibrated optics setup of DSF, it can easily view very small extra facets which can become bigger if not repaired at the initial stage thus saving repairing me. Often, these small extra facets are not even visible through Loupe.

- DSF saves overall time in terms of per facet inspection, polish related repairing as well me required to set and unset stone from the tang. This results in massive time saving for Polisher's overall produc on amount.

- Images of Diamond's surface can be saved on the computer for future evaluation purposes

- Diamond surface-related repairing is possibly none if the entire stone's polish is finalized using DSF.

Salient Features Of DSF

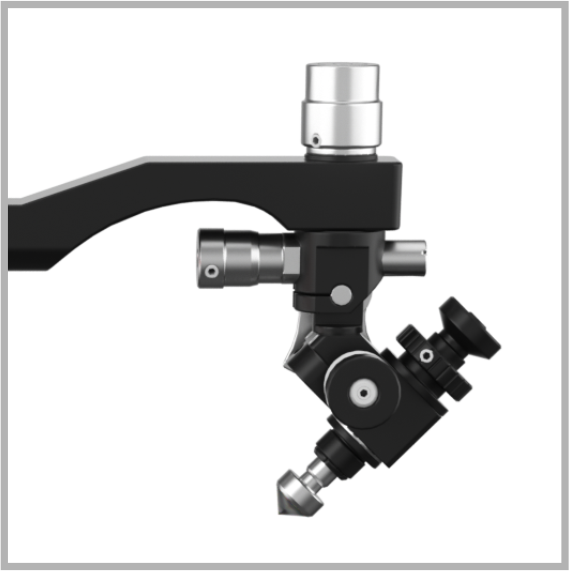

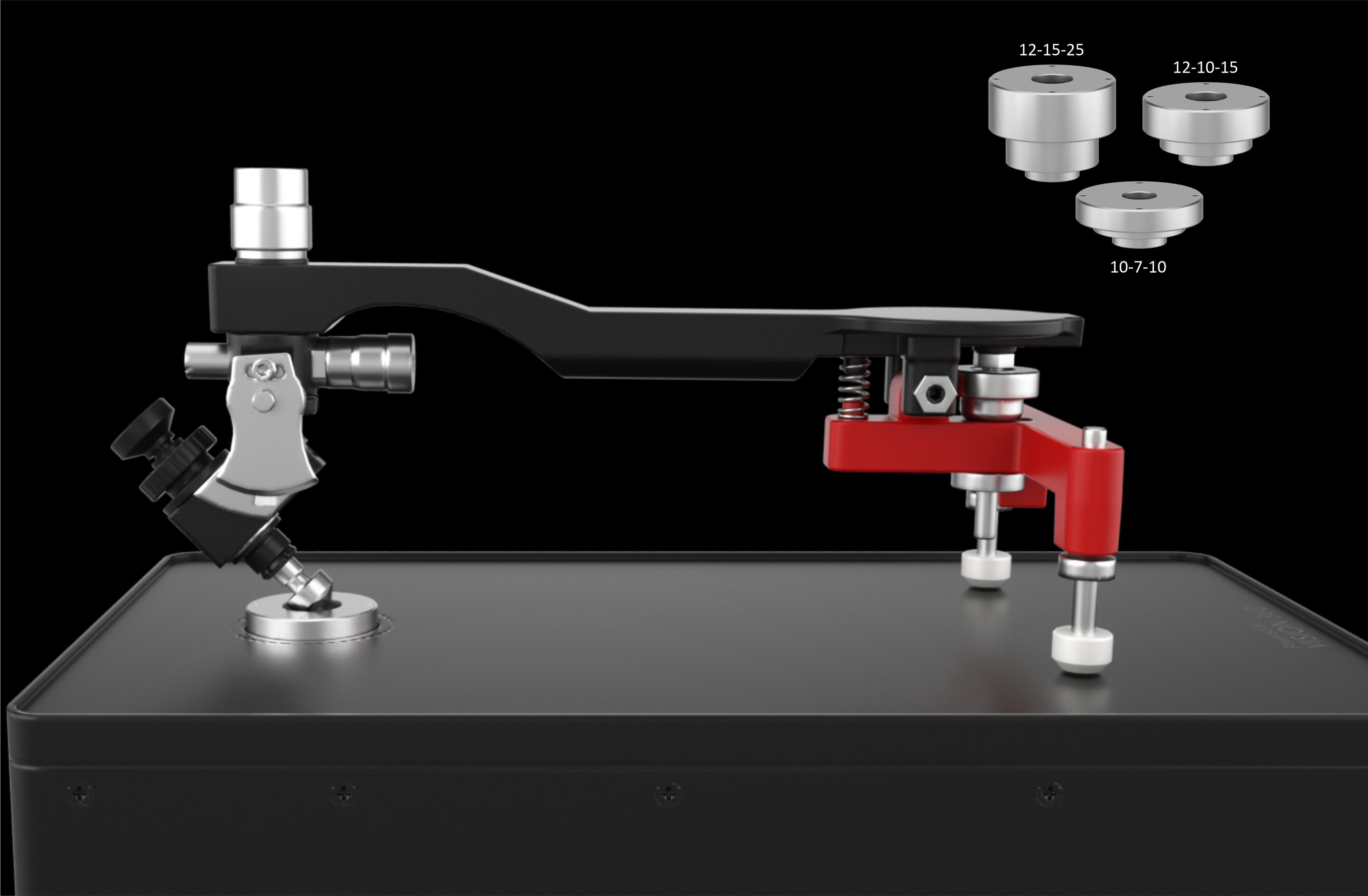

Innovative Positive air-flow design for dust-proofing the sensitive optics, very little maintenance

Important Features

Facet Searcher With White Polishing

Can visualize surface of polishing diamond while mounted in tang during process

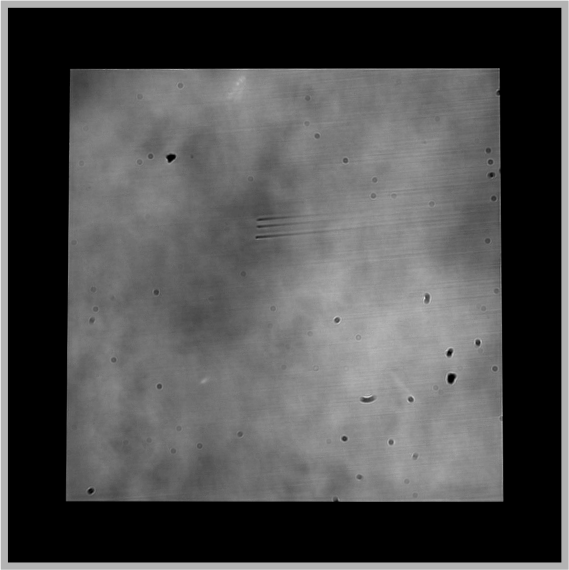

Microscopic Quality Check

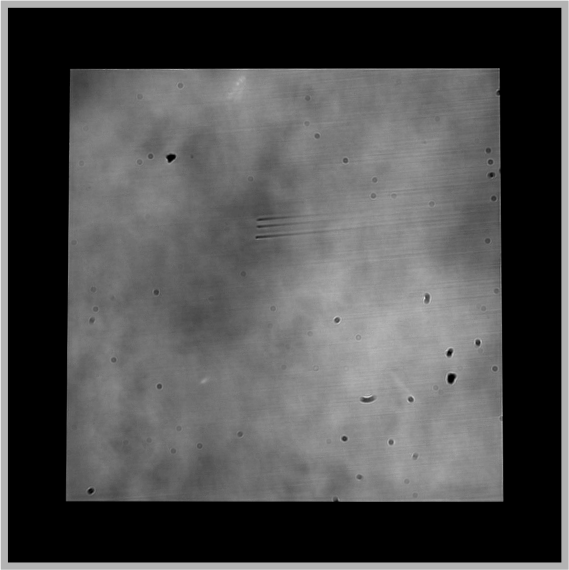

Can visualize scratches, extra facets, facet points, meeting point of facets on large screen

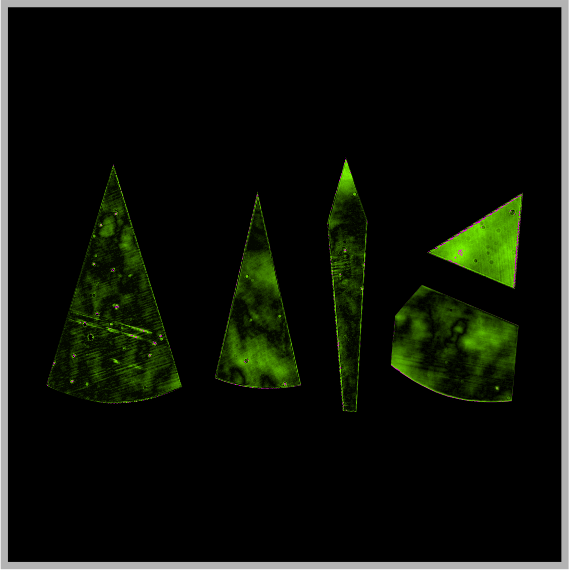

Detect Nonvisible Facets

Can visualize very small extra facets which are usually not visible or tough to locate through manual observation

Set Quality Level

Custom polish grading standards can be set which helps in standardizing final polish quality

Easy To Use

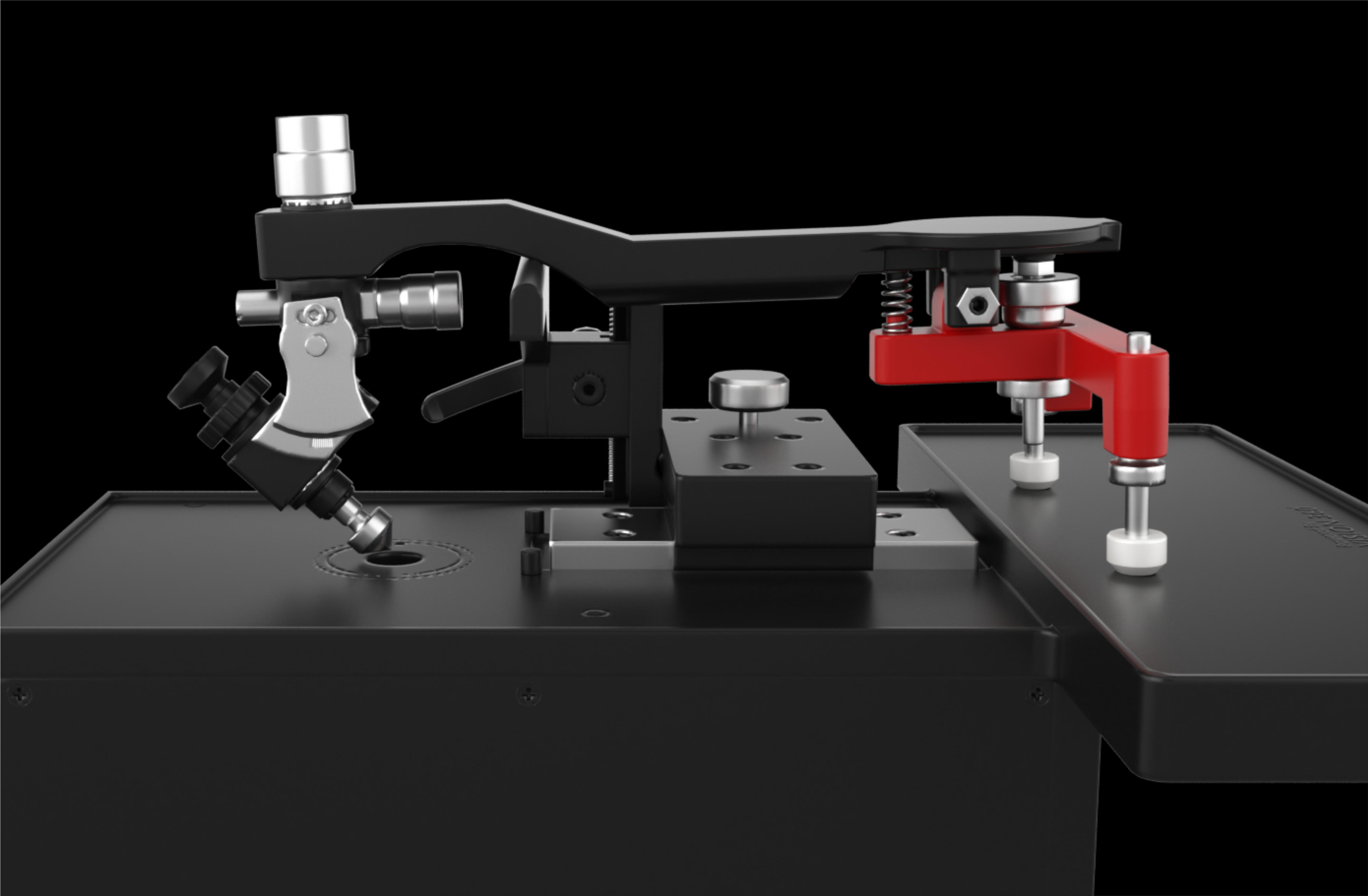

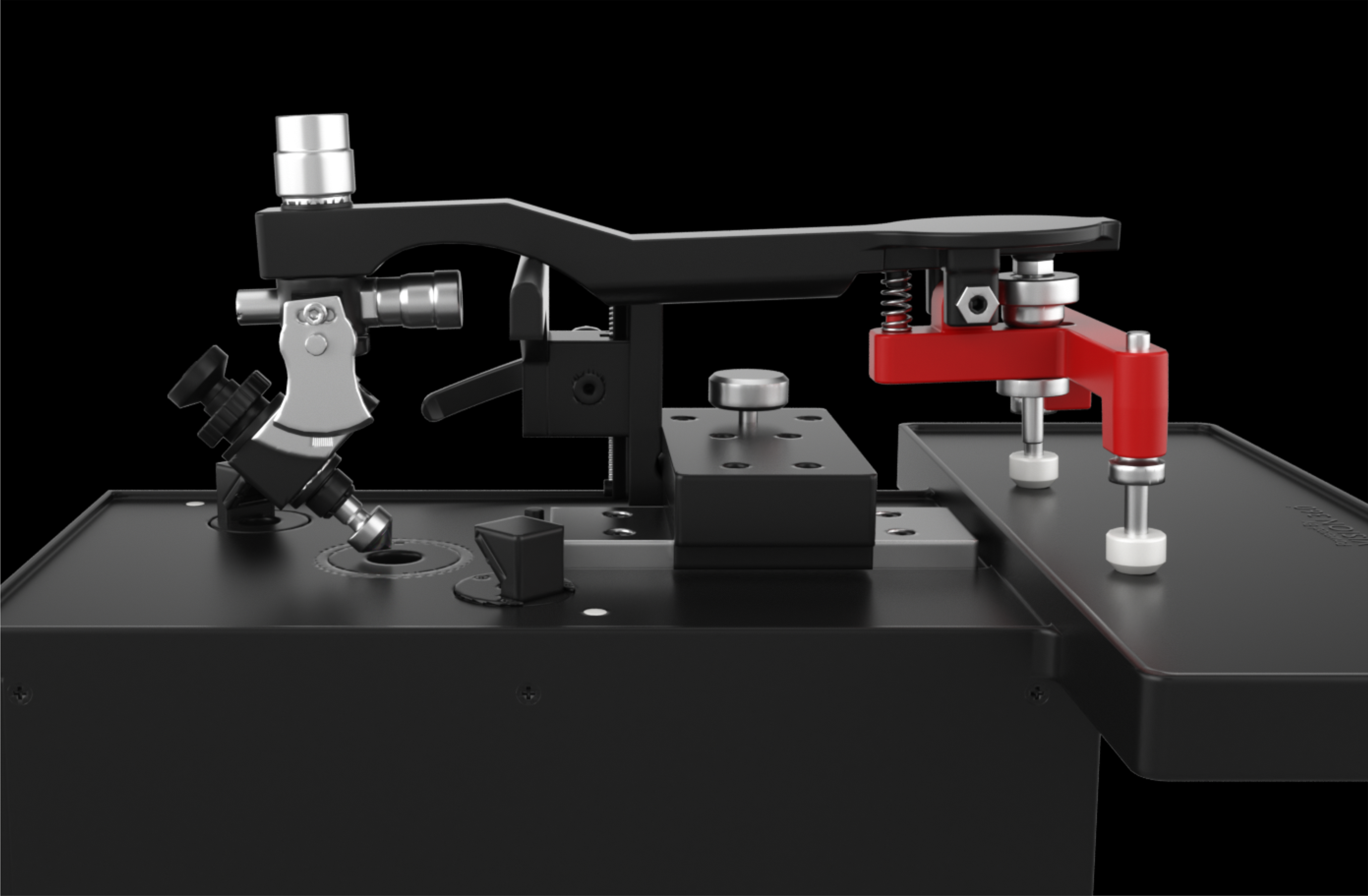

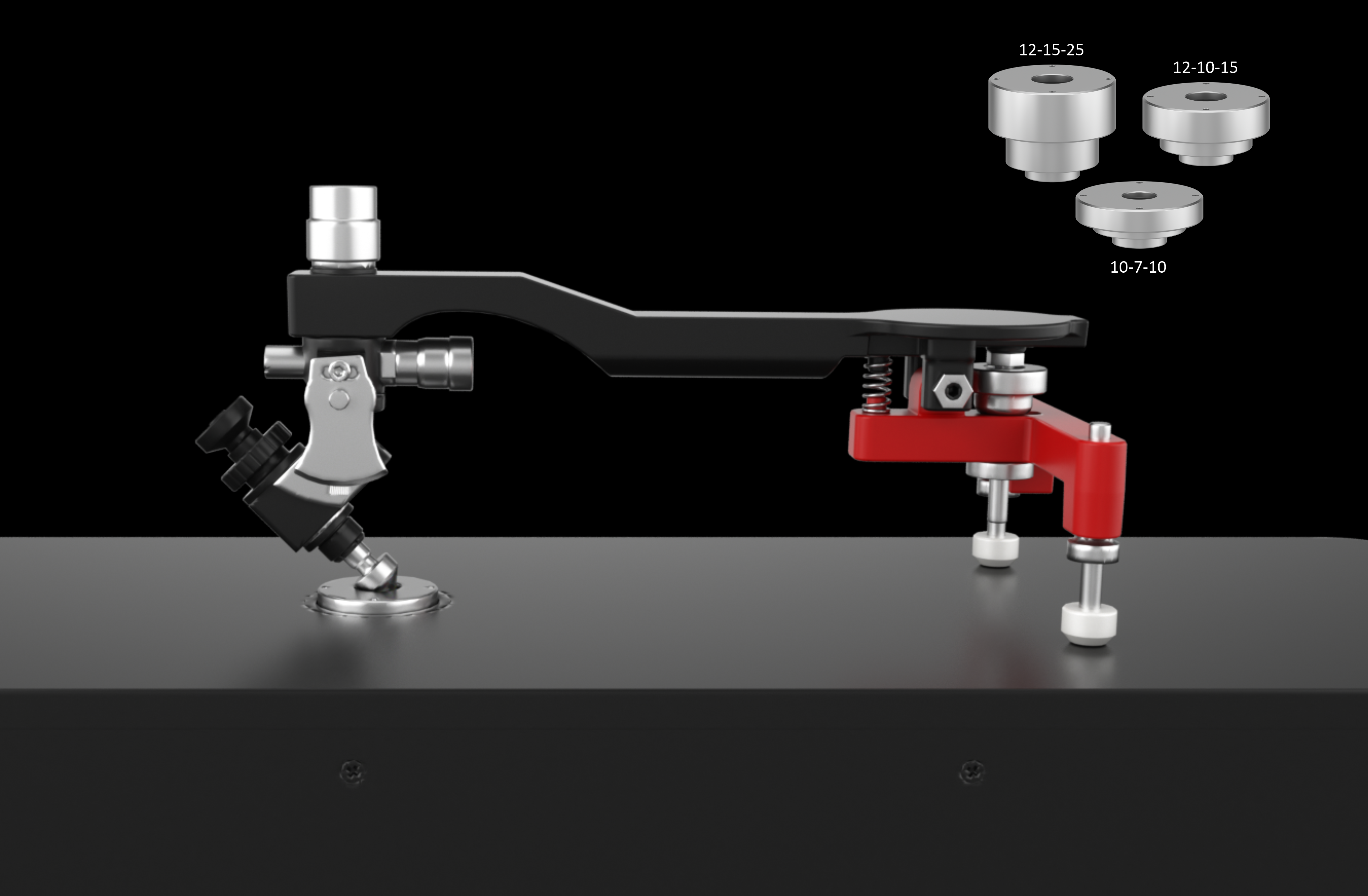

Can accommodate different types of dops and polishing tangs

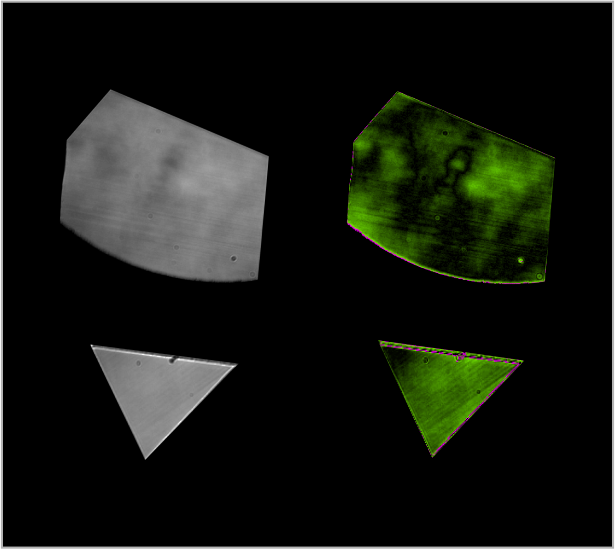

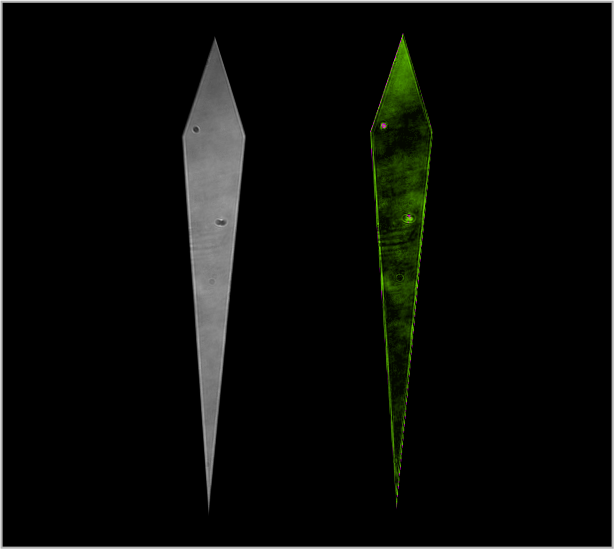

Color Coded Classification

Colour coded representation of scratches which gives clear idea of extent of polishing required

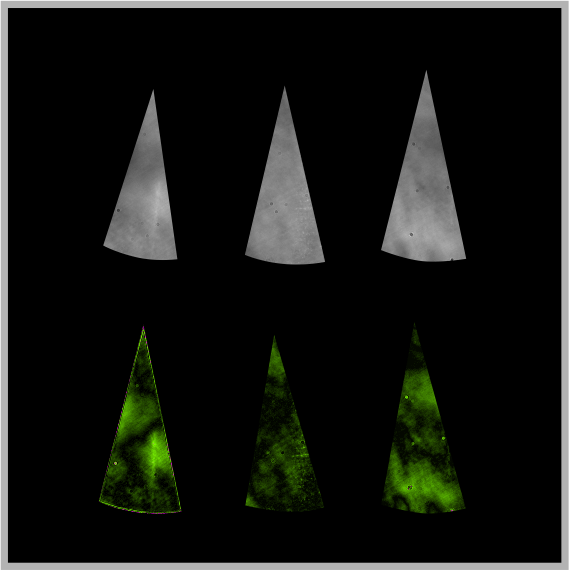

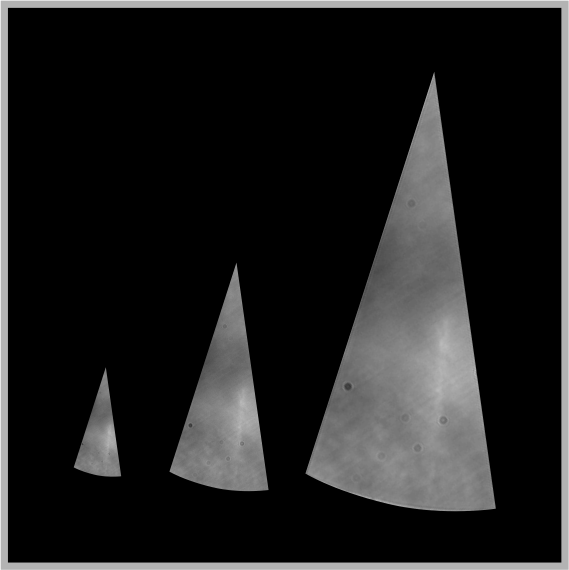

Multiple Lens Option

Multiple lens options from 3.3mm to 14mm field of view. Even larger field of view can be customised as per requirement.

Analysis During Process*

Facets can be measured during polishing process without removing from tang

Microscopic Quality Check

While inspecting the surface quality of the diamond during polishing with DSF extra efforts are required; also one requires remarkable skills. With the assistance of Assist+, one can easily view the polishing lines thus giving artificially improved images of the surface. Even an amateurish artisan can understand the scratch levels of the diamond facets without missing the details.

Analysis During Process *

While doing the table percentage, we use precise and calibrate systems so that the diameter input after the polished surface of the diamond is easily available. This process is an easy task for diamond polishing artisans. With the inclusion of Assist+ one can easily view very small extra facets that can be polished effortlessly. Therefore, it is less time consuming and thus increases the productivity.

Technical Specification

| Ideal For | Single User |

| Input Power | 110 V to 230 V AC |

| Input Frequency | 45 Hz to 60 Hz |

| Current | 0.050 to 0.120 Ampere |

| Max.Power | 10 Watt |

| Operating Temp | 10 C to 40 C |

| Weight | 10 kg |

| Dimension | L 200 mm H 272 mm D 360 mm |

| Communication Ports Required | 1 LAN Port & 1 USB Port |

| Camera | Single Camera |

| Image Resolution | 1200 x 1200 Pixels with 5.86 um pitch |

Configuration Available with Entire DSF Product Series

| Optical Magnification | 0.5X | 1.0X | 2.0X |

| Diamond Facet Viewing Size | 14 mm* | 7 mm* | 3.55 mm* |

| Min Surface Scratch Width | 25 um* | 12 um* | 6 um* |

| Ideal For | Multi Users |

| Input Power | 110 V to 230 V AC |

| Input Frequency | 45 Hz to 60 Hz |

| Current | 0.050 to 0.120 Ampere |

| Max.Power | 10 Watt |

| Operating Temp | 10 C to 40 C |

| Weight | 10 kg |

| Dimension | L 160 mm H 366 mm D 395 mm |

| Communication Ports Required | 1 LAN Port & 1 USB Port |

| Camera | Single Camera |

| Image Resolution | 1200 x 1200 Pixels with 5.86 um pitch |

Configuration Available with Entire DSF Product Series

| Optical Magnification | 0.5X | 1.0X | 2.0X |

| Diamond Facet Viewing Size | 14 mm* | 7 mm* | 3.55 mm* |

| Min Surface Scratch Width | 25 um* | 12 um* | 6 um* |

| Ideal For | Multi Users With Dops Level Assistant |

| Input Power | 110 V to 230 V AC |

| Input Frequency | 45 Hz to 60 Hz |

| Current | 0.050 to 0.120 Ampere |

| Max.Power | 10 Watt |

| Operating Temp | 10 C to 40 C |

| Weight | 10 kg |

| Dimension | L 160 mm H 366 mm D 395 mm |

| Communication Ports Required | 2 LAN ports & 1 USB port |

| Camera | Double Camera |

| Image Resolution | 1200 x 1200 Pixels with 5.86 um pitch |

Configuration Available with Entire DSF Product Series

| Optical Magnification | 0.5X | 1.0X | 2.0X |

| Diamond Facet Viewing Size | 14 mm* | 7 mm* | 3.55 mm* |

| Min Surface Scratch Width | 25 um* | 12 um* | 6 um* |

| Ideal For | Double / Four Users |

| Input Power | 110 V to 230 V AC |

| Input Frequency | 45 Hz to 60 Hz |

| Current | 0.050 to 0.120 Ampere |

| Max.Power | 10 Watt |

| Operating Temp | 10 C to 40 C |

| Weight | 21 kg |

| Dimension | L 200 mm H 272 mm D 700 mm |

| Communication Ports Required | 1 LAN Port & 1 USB Port |

| Camera | Single Camera |

| Image Resolution | 1200 x 1200 Pixels with 5.86 um pitch |

Configuration Available with Entire DSF Product Series

| Optical Magnification | 0.5X | 1.0X | 2.0X |

| Diamond Facet Viewing Size | 14 mm* | 7 mm* | 3.5 mm* |

| Min Surface Scratch Width | 25 um* | 12 um* | 6 um* |

| Measure Tolerances | +/- 12 um | +/- 6 um | +/- 3 um |