WHAT IS ASSIST+ ?

Vision 360 begins a new revolution in the field of diamond manufacturing. After various innovations in he field of the diamond and gems industry, Vision 360 is all set with the newest services to take your business one step ahead. And therefore, to empower diamond manufacturing, polishing and diamond-cut, we are introducing a new way of diamond polishing assistance

Assist +

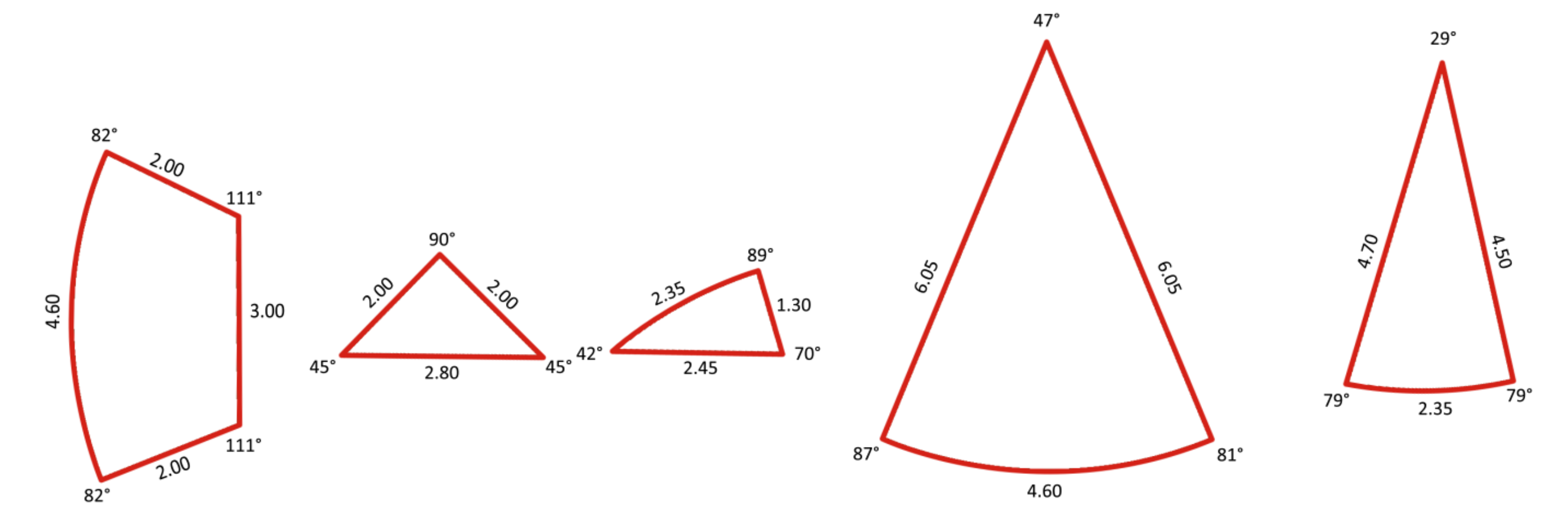

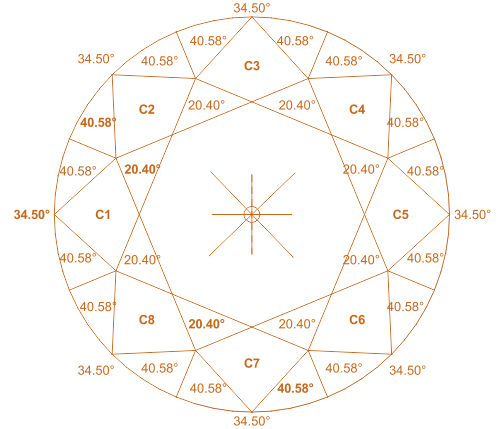

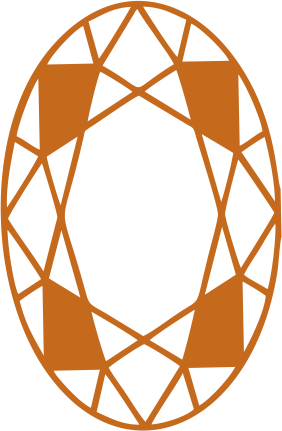

Designed scrutinizing the fresh, modern and practical approach. Generally, diamond polishing artisans are clueless about how many facets they have to polish. When they receive the planning data seized through regular methods, only angles of the diamond are provided to them. With the support of Assist+, the diamond polishing artisans will receive the practical data of how much diamond should be polished as it provides the exact dimension. On the grounds of that, the artisans can polish the diamonds as per the given measurement and the facet can be polished accordingly.

A practical approach that was never given a thought in this industry, in addition to the Measure 360 product range, we have ironed out this issue. With the help of Assist+, the artisans can also refine their skills in the initial learning process of diamond polishing.

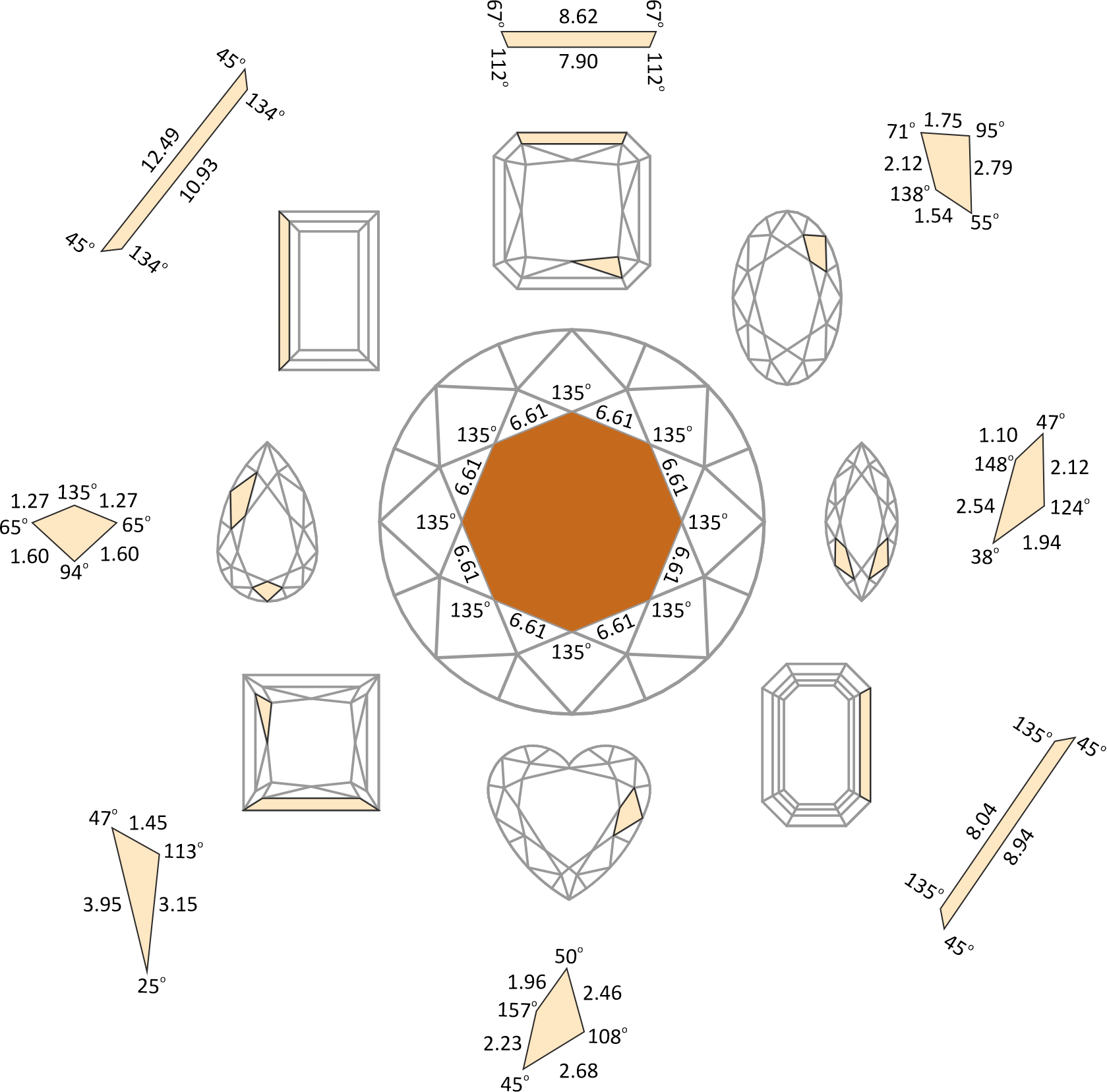

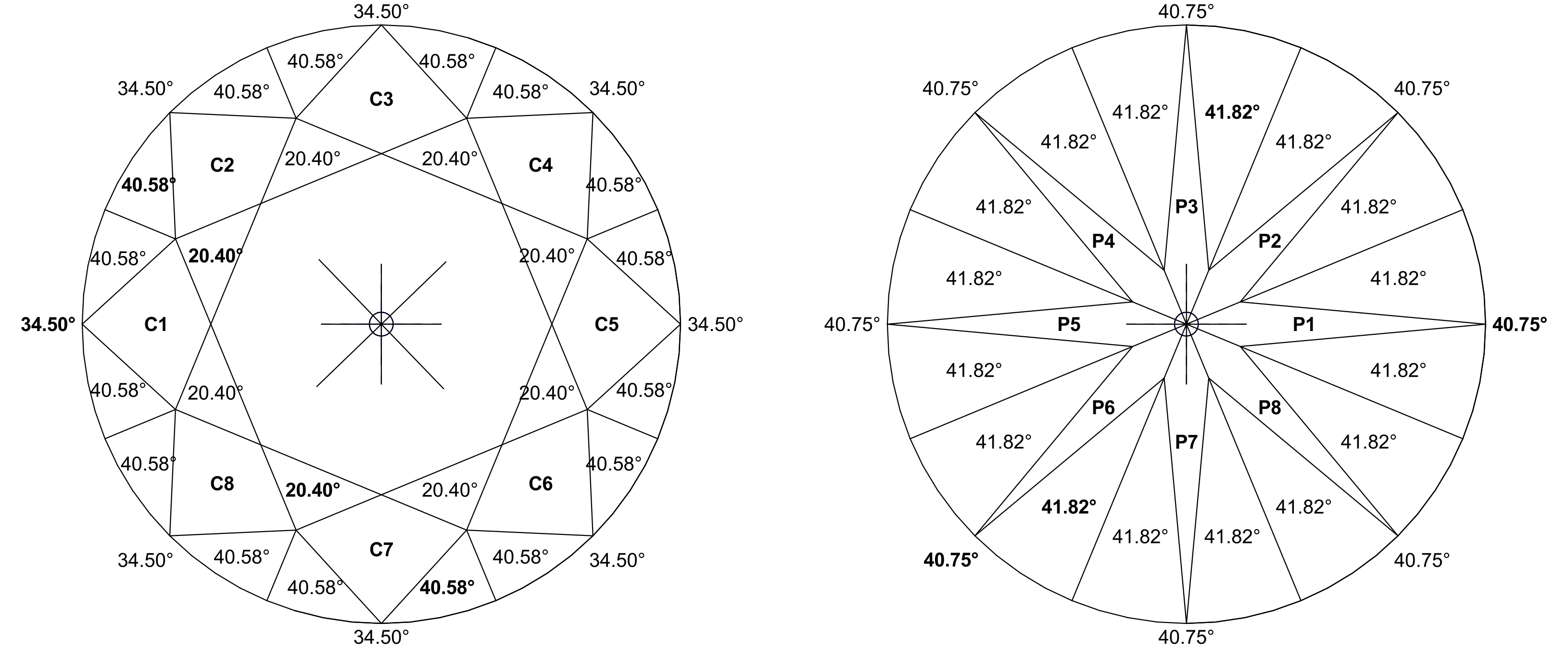

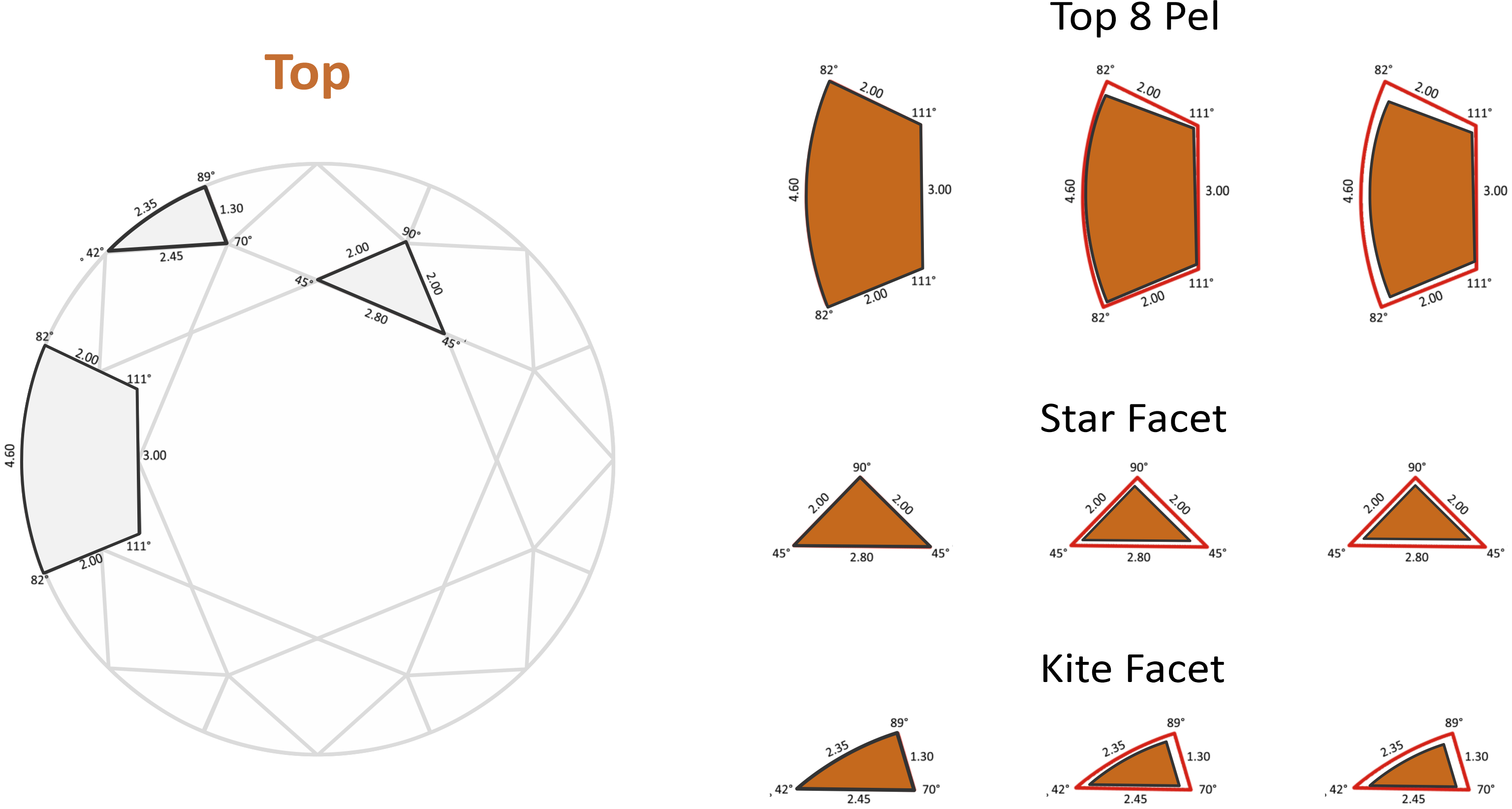

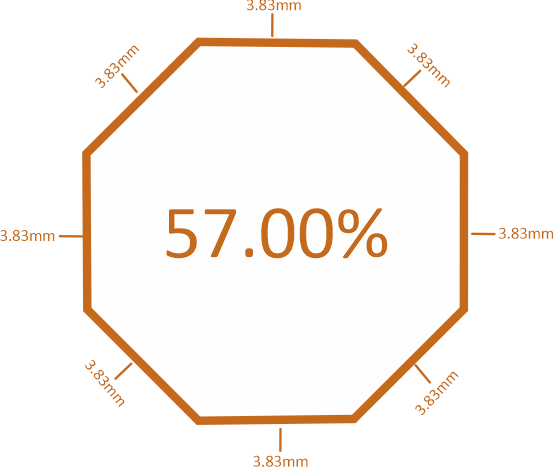

Existing Measurement System Of Facet

Various Measurement Of The Facet Taken With The Help Of Assist+

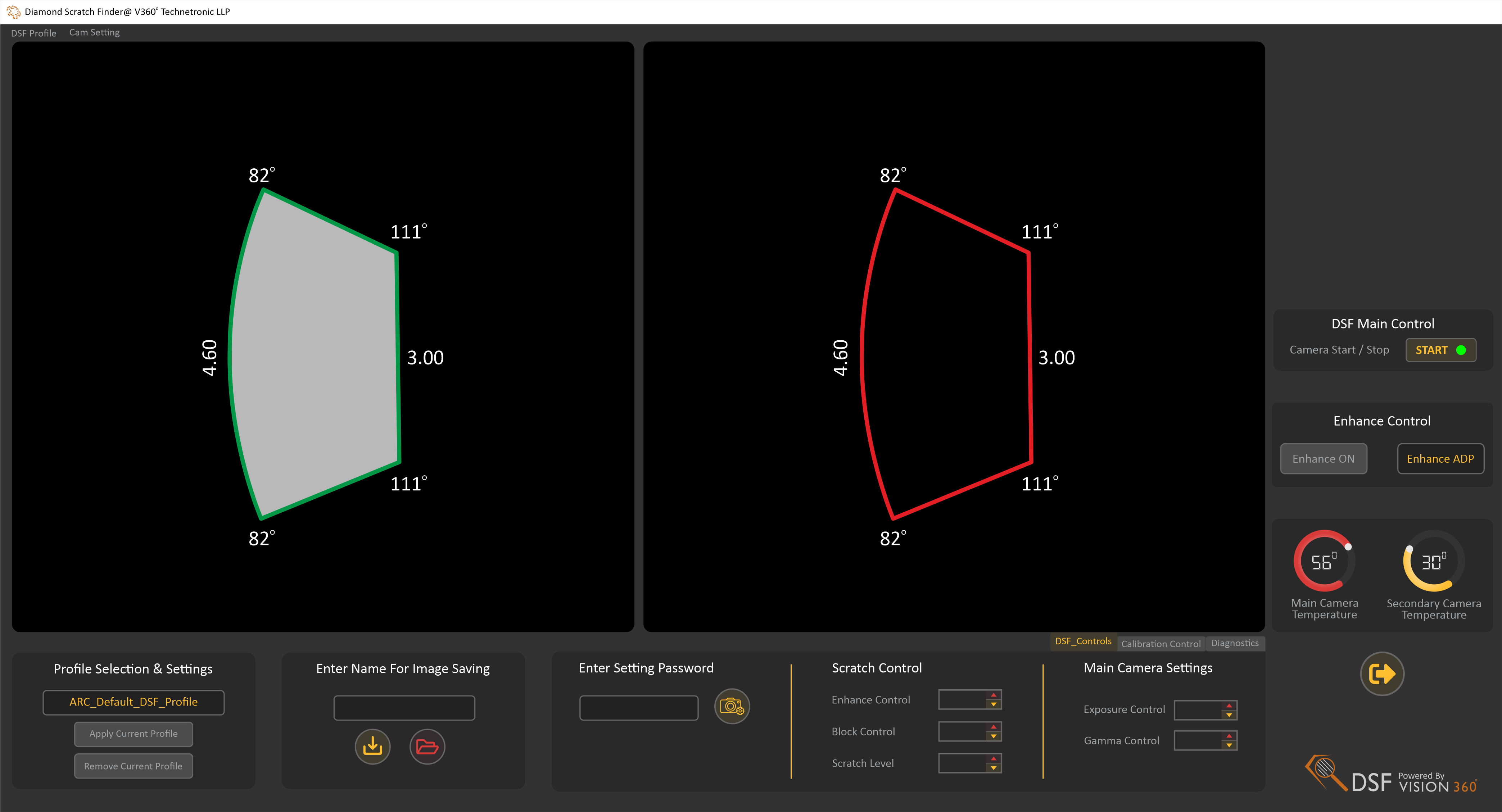

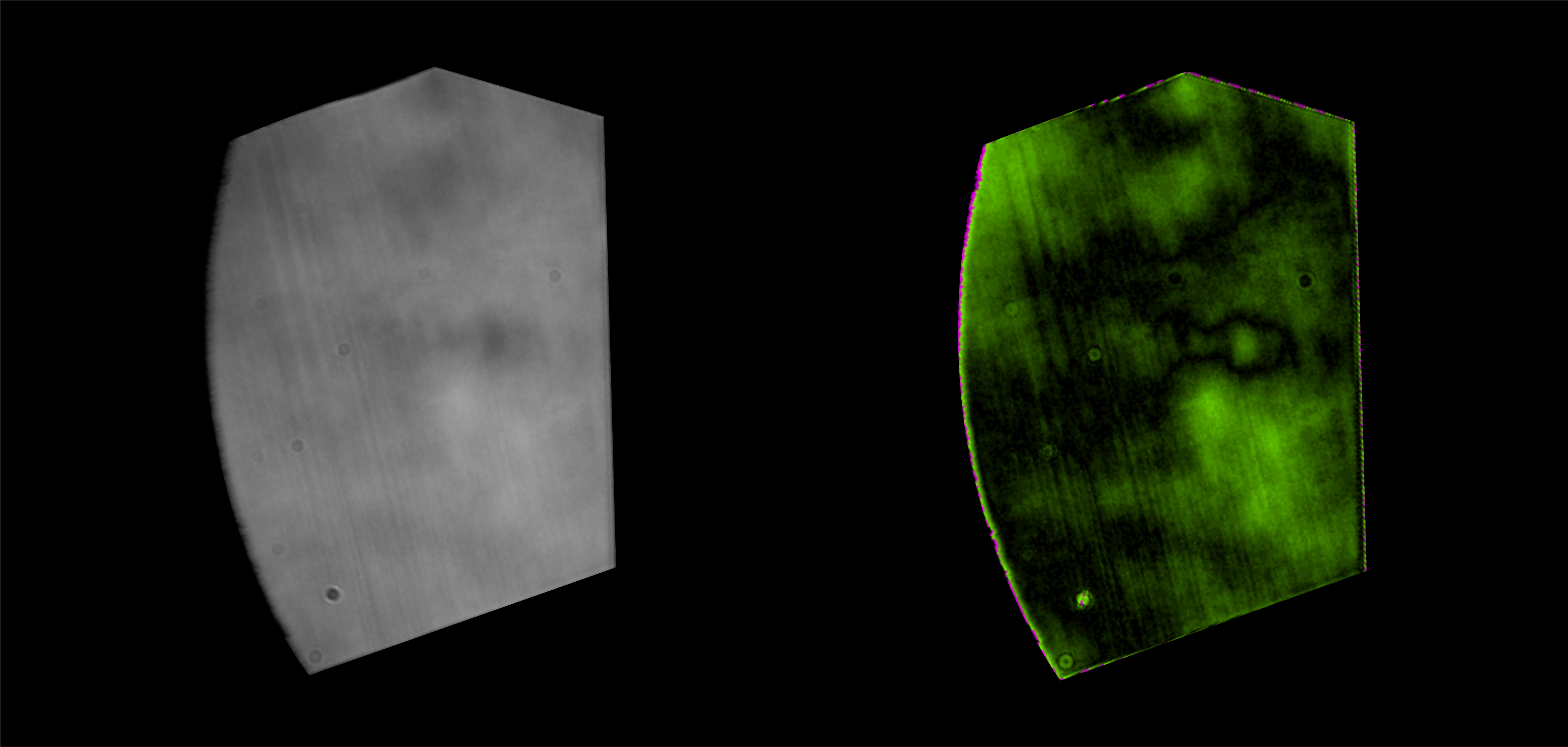

A perfect assistant for diamond polishing, Assist+ is the latest facility that will make the work of diamond polishing artisans easier. From checking the diamond polishing along with measurement to maintaining records of polishing images, Assist+ will be a seamless aide that will benefit the diamond artisans. It will help to surge the accuracy of diamond polishing giving one a flawless result. It helps diamond polishing operative and effortless as per the diamond plan.

Hassle-free and easy to operate Assist+ features in DSF as one can check the polishing line as well the measurement.

High quality polishing lines can be observed easily with this which was earlier observed only with a microscope

Assist+ features with our all diamond stretch finder series including M1, M2, U1 and U2 series

How It Works

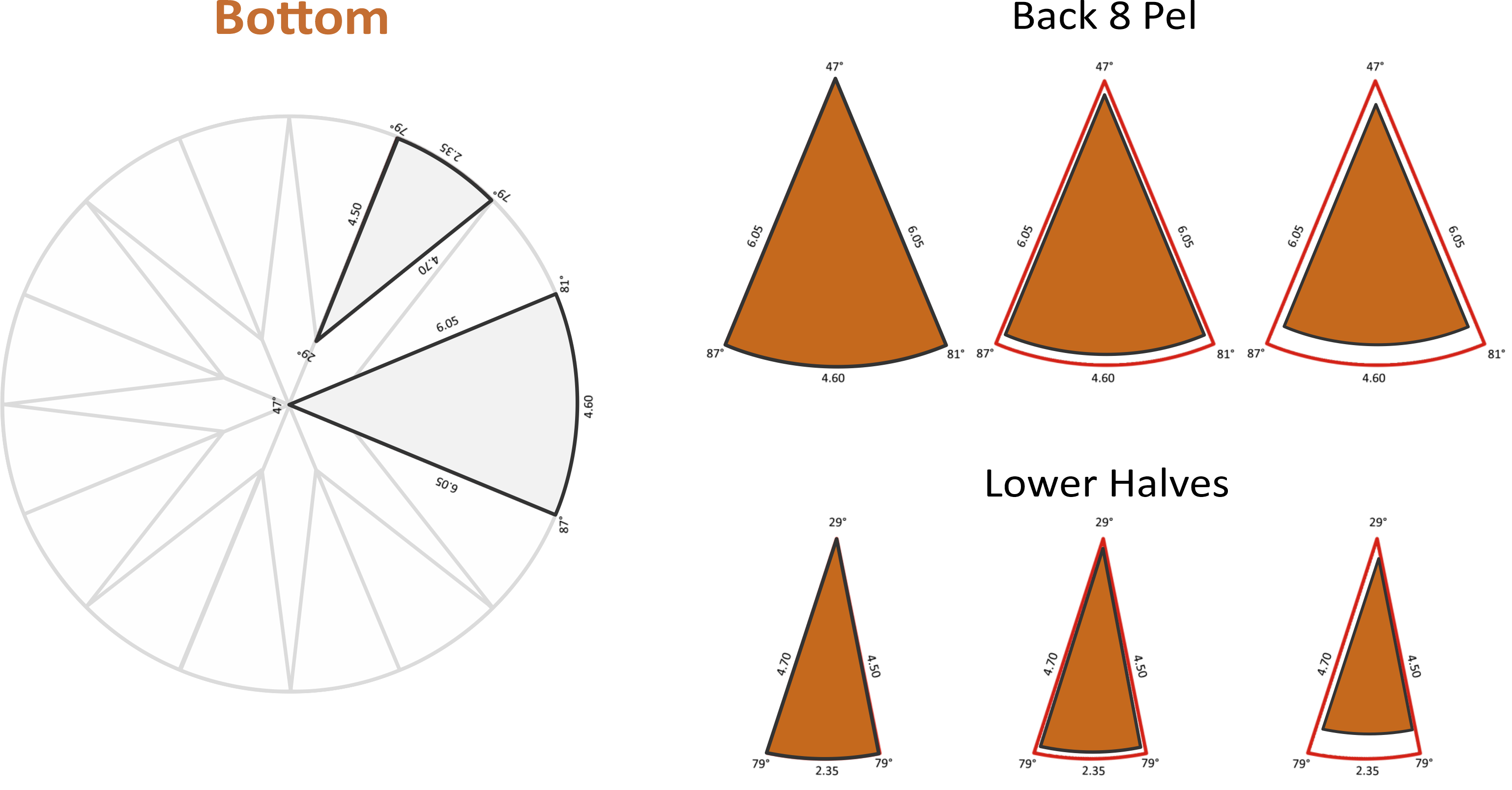

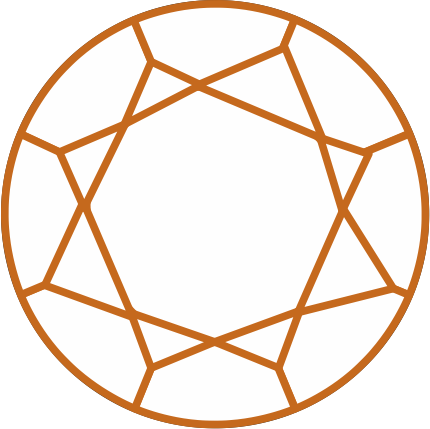

While making the facet, the final white frame of the diamond is on the screen. With the fixed parameter, the facet can be easily matched with the one on the white frame.

One can view the small, big or inclination. Also, with the set measurement of the DSF, one can measure while working on the facet.

The demonstration showcases only round diamond. This procedure is feasible in every type of diamond.

Important Features

Angle, which is available in Planning model, can be easily designed by the polishing artisan.

The two-fold (net) can be matched accurately.

The percentage of the table can be acquired.

The facet small, big or inclination of a diamond can be made with the smallest division.

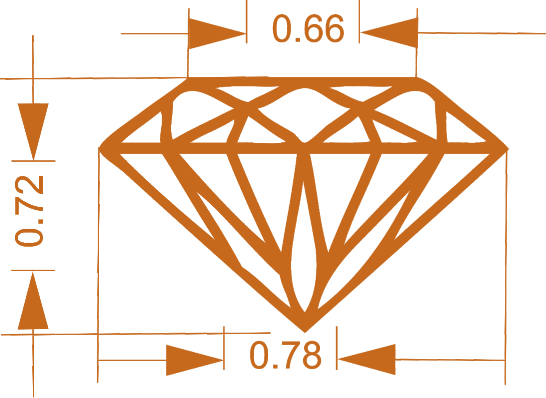

Crown, Pavillion, height %, and height deviation can be perfectly acquired.

With the help of DSF, Assist+ least experienced diamond polishing artisan can obtain a good result in symmetry and polishing. This requires less diamond measurement and also reduces the time.

The device also helps to maintain records of polishing images and measurement for further reference.

Supports global standard .stl files which are commonly generated from any planning so ware.

It works with all types of diamond shapes.