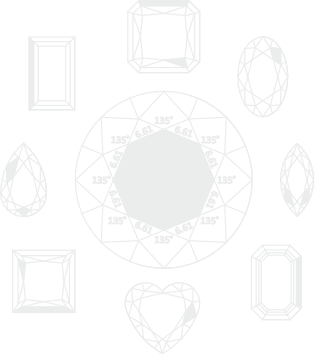

WHAT IS ASM ?

While manufacturing diamonds, it is essential to look into the accuracy of diamonds in various aspects like symmetry, diameter, variations, characteristics and many more. With the help of ASM Machine, the jewellery manufacturers, as well as B2B channels, can now easily analyse and scrutinize essential features like the symmetry of the diamond, diameter, variations in shapes, and characteristics in the least time.

With the help of ASM Machine, one can analyse the diameter, length, width, minimum and maximum deviations of the diamonds which is helpful for the end-users.

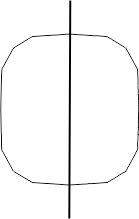

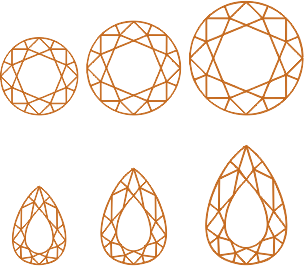

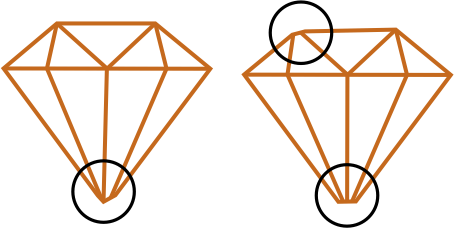

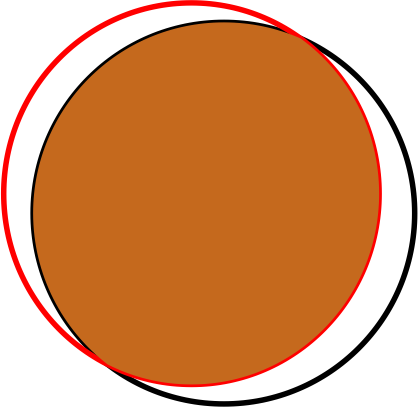

Round Shapes

Diameter

Min

1.000 mm

Min

1.000 mm

Min

1.000 mm

Min

1.000 mm

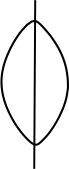

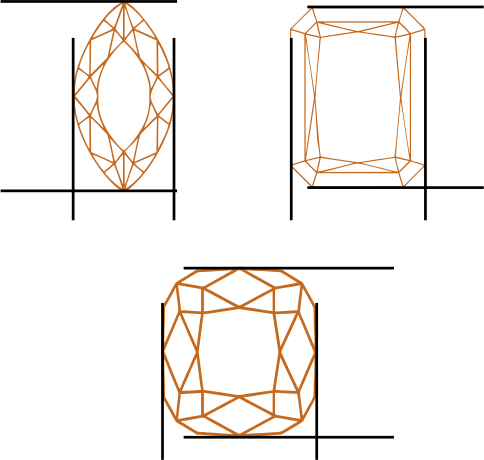

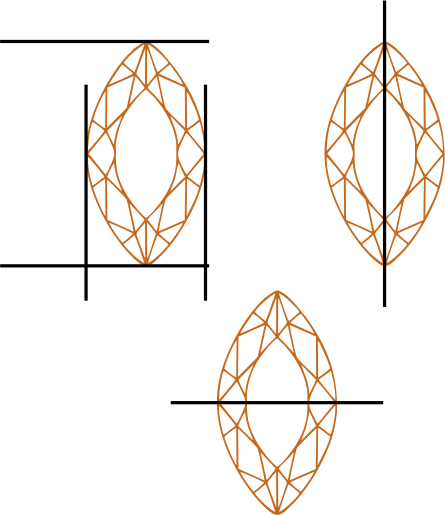

Marquise Shapes

Width

1.000 mm

Length

2.000 mm

Ratio

2.00

00%

00%

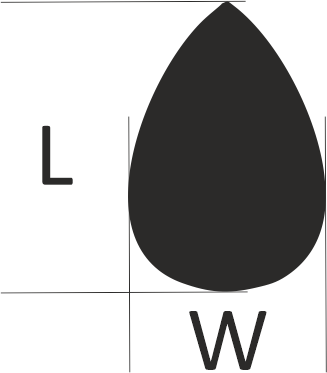

Pear Shapes

Width

1.000 mm

Length

1.500 mm

Ratio

1.50

00%

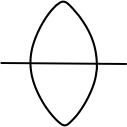

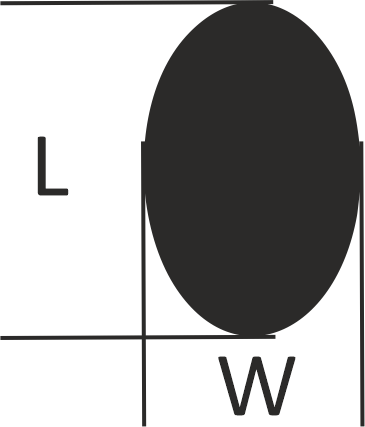

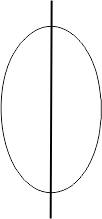

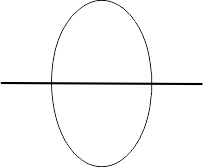

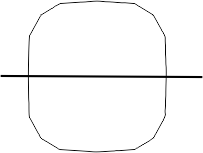

Oval Shapes

Width

1.000 mm

Length

1.500 mm

Ratio

1.50

00%

00%

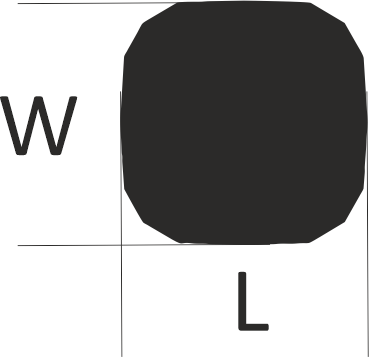

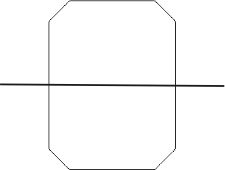

Cushion Shapes

Width

1.000 mm

Length

1.050 mm

Ratio

1.05

00%

00%

Budget Shapes

Width

1.000 mm

Length

1.500 mm

Ratio

1.50

00%

00%

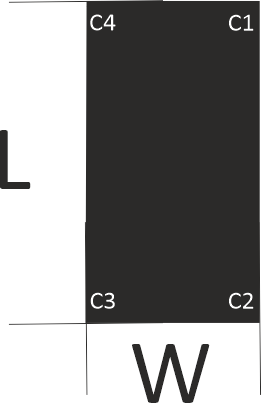

Corner

Angle Dev

C1

135°

C2

135°

C3

135°

C4

135°

Min

135°

Max

135°

Dev

0.00

Avg

135°

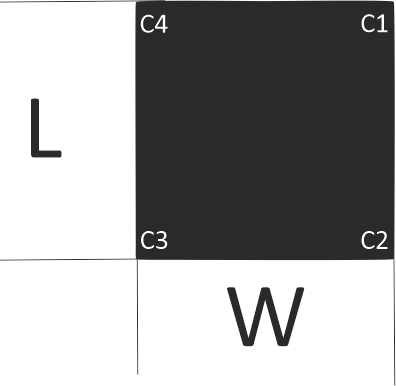

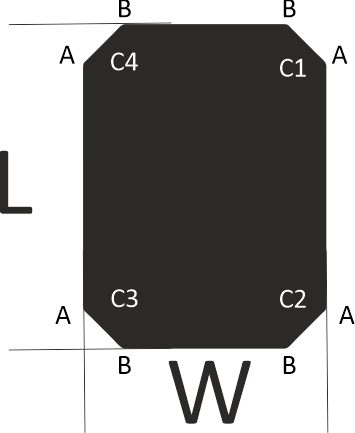

Princess Shapes

Width

1.000 mm

Length

1.050 mm

Ratio

1.05

00%

00%

Corner

Angle Dev

C1

135°

C2

135°

C3

135°

C4

135°

Min

135°

Max

135°

Dev

0.00

Avg

135°

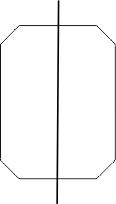

Emerald Shapes

Width

1.000 mm

Length

1.500 mm

Ratio

1.50

00%

00%

Corner A

Angle° B

C1

135°

135°

C2

135°

135°

C3

135°

135°

C4

135°

135°

Min

135°

135°

Max

135°

135°

Dev

0.00

0.00

Avg

135°

135°

Corner Angle %

5%

5%

5%

5%

5%

5%

5%

5%

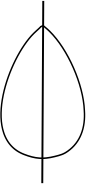

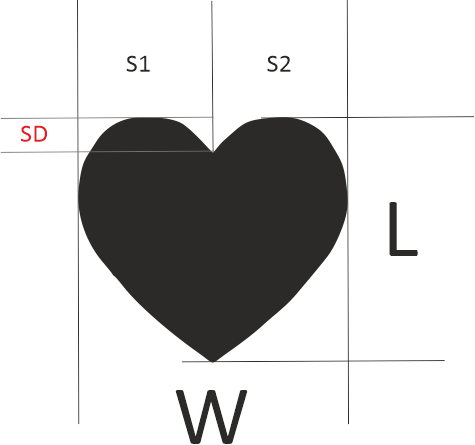

Heart Shapes

Width

1.050 mm

Length

1.000 mm

Ratio

0.952

Shoulder Depth

15%

00%

S1

0.000 mm

S2

0.000 mm

DEV S1/S2

0.00

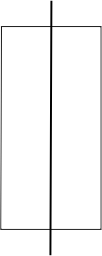

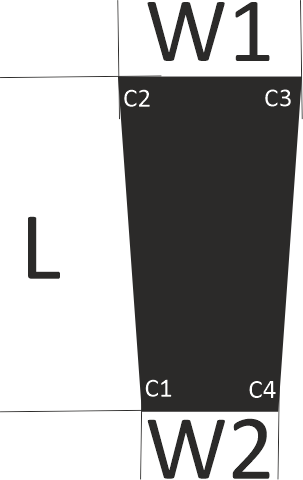

Tapper Shapes

Width

1.000 mm

1.000 mm

Length

1.500 mm

1.500 mm

Ratio

1.50

1.50

00%

Corner

Angle Dev

C1

135°

C2

135°

C3

135°

C4

135°

Min

135°

Max

135°

Dev

0.00

Avg

135°

Benefits Of ASM

The instrument also deliver results in seconds. Now get the dimension of the diamond just in one second

The drifting of curates in diamonds, especially in round diamonds, can be avoided.

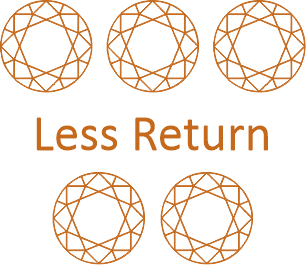

As the accuracy of the diamonds has increased, the return of the goods has also lessened gradually.

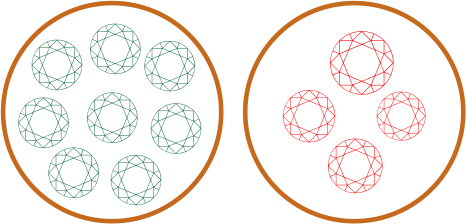

The machines are designed for any type of diamond. Whether it is small or big diamonds, it increases the productivity of the diamonds. It is a trade model design which helps in easy workflow.

The machines are designed for the fast production of diamonds. Thus, it has both, hand switches and foot paddles, making the work easy.

Important Features

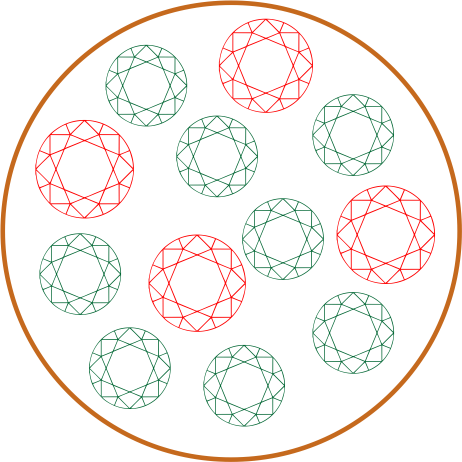

While manufacturing diamonds, the major issues faced by manufacturers are the sieve size and size difference which results in the inaccuracy of size. With the support of the ASM Machine, the sieving and size difference problems no longer exist.

The problems faced due to the size difference or sieving size, there is a huge quantity in return of goods. With the introduction of this machine, the returns will be reduced.

It rifts that occurs while sieving the fine diamonds doesn’t crop up with this machine.

The accuracy of various deviations can be easily inspected with the help of ASM machine.

The manufacturers and B2B channels can use it as a gauge for effortless access to diamond analysis. It is also helpful to analyse fine diamonds.

Often, it is difficult to detect the deviation or symmetry in various shapes and sizes of diamonds manually. With the help of ASM Machine, these works become uncomplicated and effortless.

Technical Specification

| Ideal For | Single User |

| Input Power | 110 V to 230 V AC |

| Input Frequency | 45 Hz to 60 Hz |

| Current | 0.050 to 0.120 Ampere |

| Max.Power | 10 Watt |

| Operating Temp | 10 C to 40 C |

| Weight | 000 Kg |

| Dimension | L 000 mm H 000 mm D 000 mm |

| Communication Ports Required | 1 LAN Port & 1 USB Port |

| Camera | Single Camera |

| Image Resolution | 1200 x 1200 Pixels with 5.86 um pitch |

Configuration Available with Entire Measure Product series

| Optical Magnification | 0.5X | 1.0X | 2.0X |

| Diamond Facet Viewing Size | 14 mm* | 7 mm* | 3.5 mm* |

| Measure Tolerances | +/- 12 um | +/- 6 um | +/- 3 um |

*Approximate

Calibration: Each machine is calibrated and verified using optical targets to achieve acceptable accuracy.

Note: Consistency of every piece from the same model is related to the type of optical lens is chosen. Customers can opt for higher consistency upon request.